TURBOEXPANDERS

We offer aftermarket support as well as full package turboexpander designs to support a wide range of applications, including: liquefaction, peak shaving, chemical/petrochemical, air separation, organic rankine cycle, and energy recovery.

Machine Configurations

Turboexpanders have three mechanical configurations, with limitless customization. Depending on the application and process conditions, these configurations can be single stage or multiple stage units.

EXPANDER

COMPRESSOR

APPLICATIONS

- Liquefaction

- Refrigeration

- Peak Shaving

- Petrochemical

- Air Separation

- Hydrocarbons

Expander-Compressors are highly customizable machines that can support a wide variety of applications.

This piece of equipment is ideal for liquefaction or cryogenic processes with high-pressure gas mixtures. In addition, this equipment is beneficial for peak shaving, and air separation applications.

EXPANDER

GENERATOR

APPLICATIONS

- Energy Recovery

- Pressure Let-Down

- Geothermal

- Organic Rankine Cycle (ORC)

Expander-Generators are ideal for applications which seek to recover energy within a process in order to generate power.

This includes simple pressure letdown stations where a valve could be replaced with an Expander-Generator allowing a company to capitalize on the pressure differential to create energy.

EXPANDER

DYNAMOMETER

APPLICATIONS

- Low-Speed Applications

- Refrigeration

Expander-Dynamometers are typically utilized in low flow applications where refrigeration is the goal.

This piece of equipment is only utilized in applications where the economic payoff does not necessitate a compressor or generator load, instead of using a fluid brake load to dissipate energy.

EXPANDER

COMPRESSOR

APPLICATIONS

- Liquefaction

- Refrigeration

- Peak Shaving

- Chemical

- Petrochemical

- Air Separation

- Hydrocarbons

Expander-Compressors are highly customizable machines that can support a wide variety of applications. These pieces of equipment are ideal for liquefaction or cryogenic processes with high-pressure gas mixtures.

EXPANDER

GENERATOR

APPLICATIONS

- Energy Recovery

- Pressure Let-Down

- Geothermal

- Organic Rankine Cycle (ORC)

Expander-Generators are ideal for applications which seek to recover energy within a process in order to generate power. This includes simple pressure letdown stations where a valve could be replaced with an Expander-Generator to capitalize on the pressure differential to create energy.

EXPANDER

DYNAMOMETER

APPLICATIONS

- Low-Speed Applications

- Refrigeration

Expander-Dynamometers are typically utilized in low flow applications where refrigeration is the goal. These piece of equipment are only utilized in applications where the economic payoff does not necessitate a compressor or generator load, instead of using a fluid brake load to dissipate energy.

FULL PACKAGES

From preliminary design to manufacturing to final on-site commissioning, SMI oversees all project management and service support for new, full package skid units. Once the project begins, the project engineer in charge has direct communication with the customer to ensure that all specialty design needs are made to the customer’s satisfaction.

Our customized machines are designed to reduce or remove critical no-run zones and attain the highest possible efficiency for whatever your application may be. We also ensure that engineers are made available for customer support so that each and every customer has personal support for their projects.

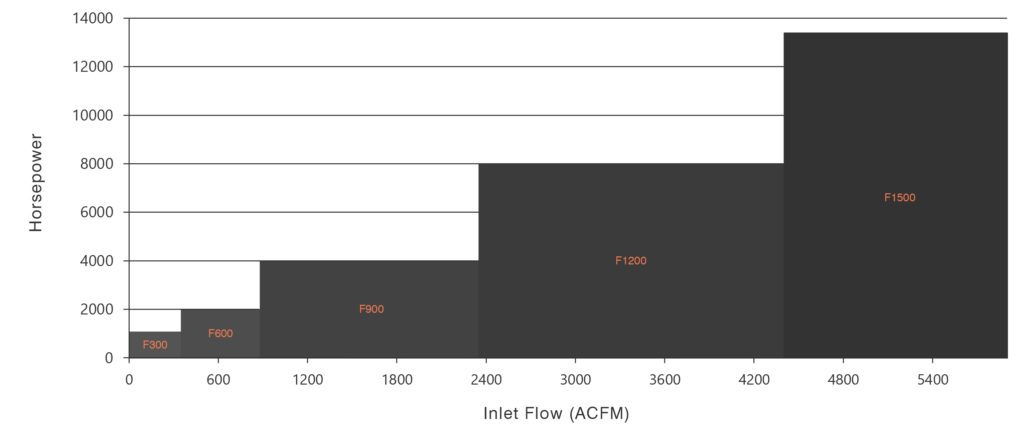

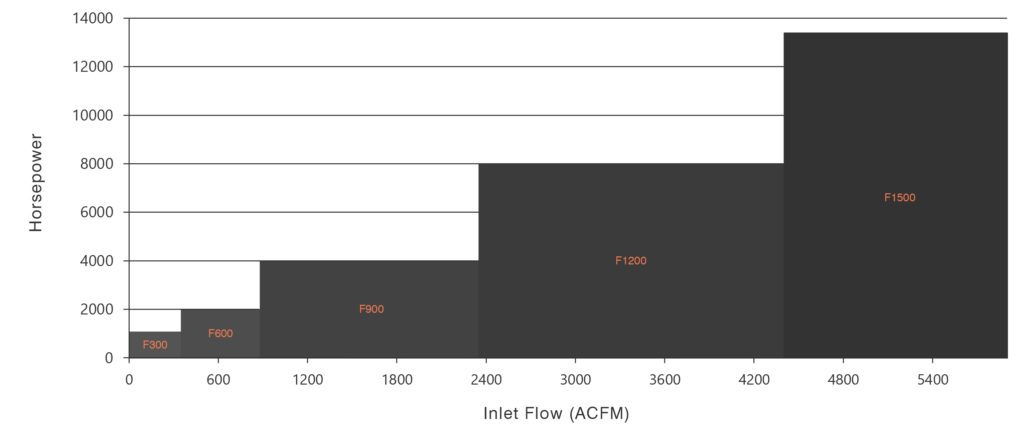

Package Specs

We have 5 nominal frame sizes from which we customize all internal components to attain the highest efficiency for each customer’s unique process conditions. These units can be single or multiple stage units, depending on the process conditions Below are the nominal operating condition ranges for each frame size.

FULL PACKAGES

From preliminary design to manufacturing to final on-site commissioning, SMI oversees all project management and service support for new, full package skid units. Once the project begins, the project engineer in charge has direct communication with the customer to ensure that all specialty design needs are made to the customer’s satisfaction.

Our customized machines are designed to reduce or remove critical no-run zones and attain the highest possible efficiency for whatever your application may be. We also ensure that engineers are made available for customer support so that each and every customer has personal support for their projects.

Package Specs

We have 5 nominal frame sizes from which we customize all internal components to attain the highest efficiency for each customer’s unique process conditions. These units can be single or multiple stage units, depending on the process conditions Below are the nominal operating condition ranges for each frame size.

Bare Machine Units

We offer bare machines for customers who wish to final package the skid themselves. This ensures that all critical rotating equipment and design is handled by SMI, while all non-critical secondary components and packaging is handled by the customer.

For Expander-Compressors, the bare machine would be the entire mechanical rotating center section. For Expander-Generators, the bare machine – also referred to as “bare shaft machine” – would be the expander rotating section and gearbox; referred to as the Expander Power Unit (EXPU). The motor and all other support systems would be purchased and packaged by the customer. For Expander-Dynamometers, the bare machine would include the brake system.

Have Questions?

Don’t hesitate to contact us directly at +1 805 349 2540

Have Questions?

Don’t hesitate to contact us directly at +1 805 349 2540