PARTS

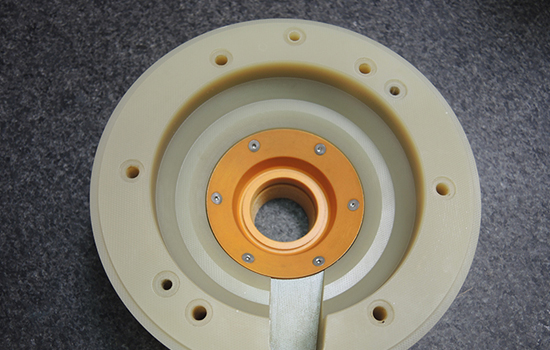

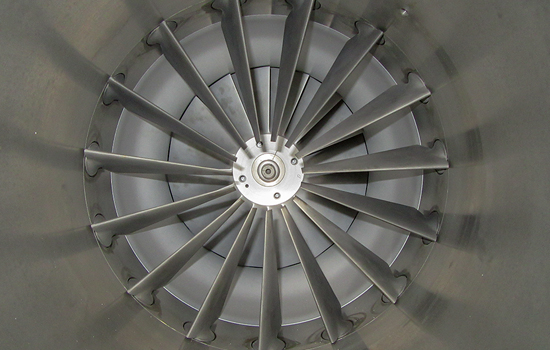

We offer aftermarket support of all internal parts, regardless of the OEM. Why wait for a damaged part to create costly downtime – order spare parts today and ensure your machine always remains functional.

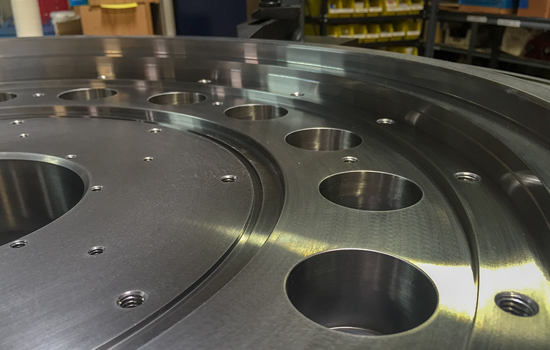

Quality, Fit, and Function

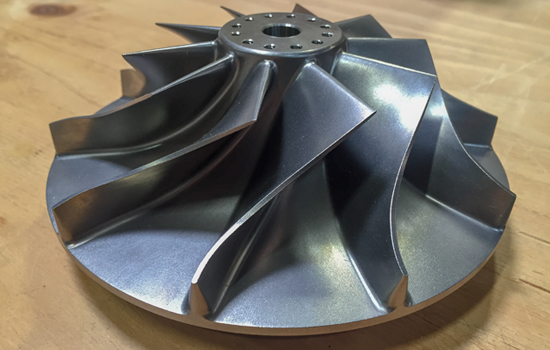

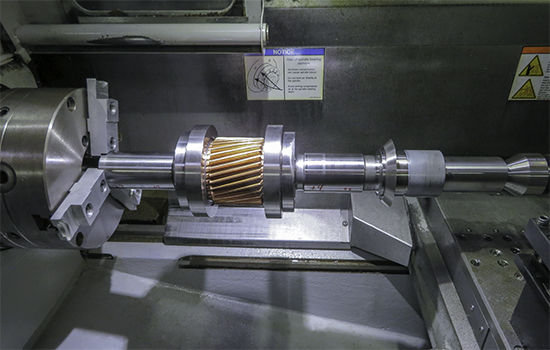

Manufacturing

We utilize 5-axis mills, CNC lathes and manual lathes to manufacture parts in-house; guaranteeing the highest quality parts with fast delivery.

What previously took months to manufacture – such as Impellers – can now be completed within a matter of weeks. In-house manufacturing also reduces cost of manufacturing, which allows us to pass the savings on to our customers.

Have Questions?

Don’t hesitate to contact us directly at +1 805 349 2540

Have Questions?

Don’t hesitate to contact us directly at +1 805 349 2540